What is a transmission when it comes to your vehicle? A transmission is another name for a car’s gearbox, the component that turns the engine’s power into something the car can use. Simply, without it, you’d sit in your car with the engine running, going nowhere.

In this tutorial we’ll explain exactly what a transmission is and how it works, starting with the most common transmission: the manual gearbox.

Manual transmission

You need gears because without them the engine would turn so quickly it would probably destroy itself. Not only that, you wouldn’t go very fast. Drive your car around in first gear, at speed. See how the engine races and after a while, you don’t go any faster?

The gears in a gearbox get around this problem. They are of progressively different sizes and multiply the engine’s torque, or ‘pulling power’, so you don’t need to rev it. By changing gear you can keep the engine in its ‘power band’, where it runs best.

The gears are brought into play by a selector operated by the gear lever. However, selection can only be made when the engine and the gearbox are disconnected from each other. This is done by means of the clutch. Press your hands together.

Imagine one hand is the gearbox side and the other, the engine side. Pressing them together enables the engine to drive the gearbox. Now separate them. The gearbox is no longer driven, allowing you to select a fresh gear without it ‘crunching’.

In place of your hands, the clutch uses grippy, spring-loaded plates operated by the clutch pedal. One plate is called the pressure plate and is bolted to the engine flywheel (a big wheel turned by the engine).

The other is called the driven plate and sits on the input shaft to the gearbox. When you press the clutch pedal, you relax the springs’ clamping pressure, so separating the engine from the gearbox.

Automated manual transmission (or semi-automatic transmission)

This transmission has an automatic clutch that allows you to change gears without operating a clutch pedal.

Sensors, actuators and processors do the job of operating the clutch as you change gear, and at exactly the right moment so there’s no gear crunching.

Instead of a gearlever you can change gear using paddles on the steering column. Automated manual transmissions are becoming less common but Peugeot markets one under the brand name ETG (efficient tronic gearbox).

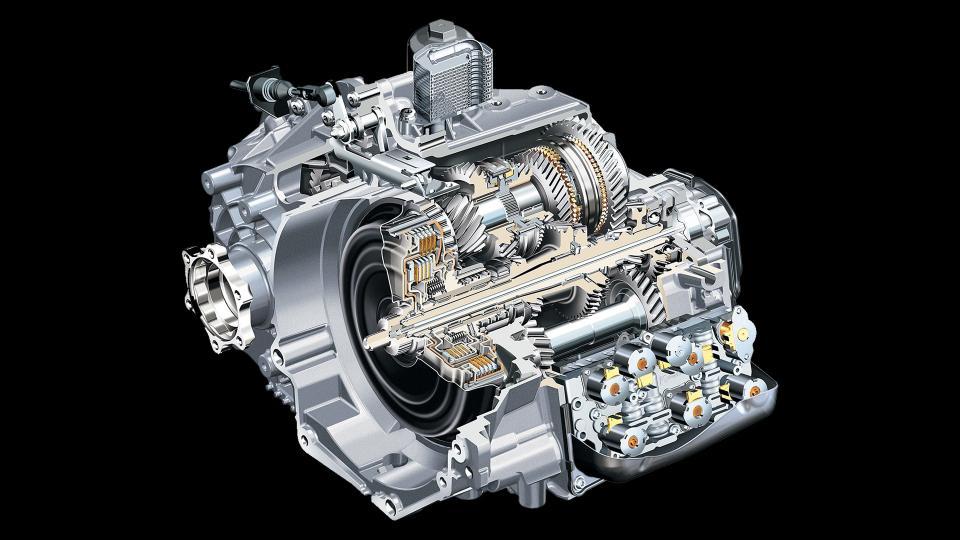

Dual-clutch transmission

This is a variation on an automated manual transmission. It goes one better by not only looking after the operation of the clutch (in fact, there are two) but also the gear changes, which you can do via paddles (it can change gear automatically, too).

Each clutch takes care of odd or even-numbered gear sets. The idea is for the system to pre-select the next gear, up or down, as you activate the previous one. This means that when you come to initiate the next change, it happens instantly without any interruption in power or progress.

Volkswagen Group markets many dual-clutch systems under brand names including S Tronic (Audi), DSG (VW), and PDK (Porsche).

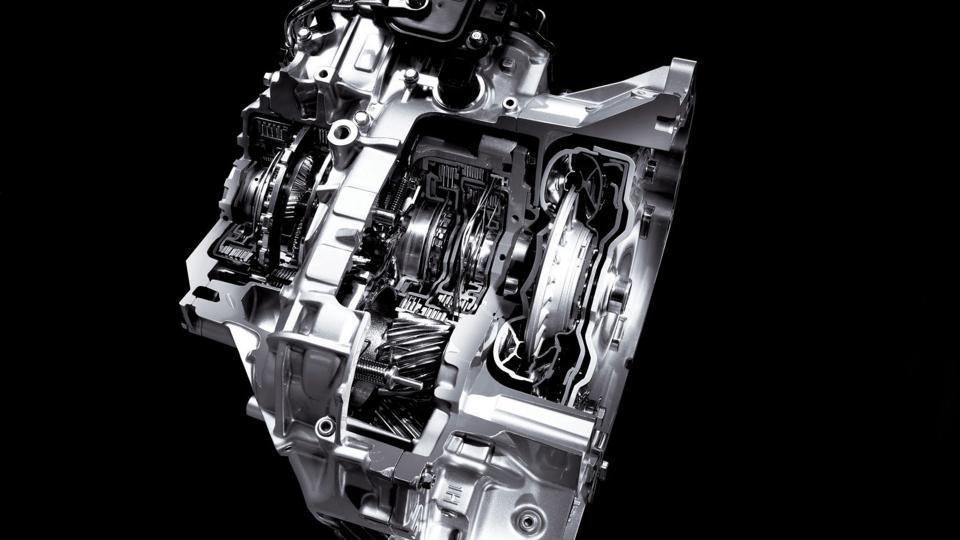

Fully automatic transmission

In place of a mechanical clutch, an automatic gearbox uses fluid to connect the engine to the gearbox. However, the fluid only does its job when it’s being spun by the engine. The fluid lives inside a donut-shaped chamber.

The side nearest the engine, and connected to the flywheel, is called the impeller and the one nearest the gearbox is called the turbine. Apart, called the stator, sits between them. This whole assembly is called the torque converter.

The stator amplifies the power of the spinning oil at low speeds by directing more of it towards the impeller, so helping to drive the turbine and ultimately the gearbox.

Inside the gearbox is something called a planetary gear set which looks like it sounds. Three or four smaller gears ‘orbit’ a central ‘sun’ gear within a larger outer ring gear.

The smaller gears are always engaged and rotate between the sun and ring gears. As the torque converter spins, it drives a pump which pumps fluid inside the gearbox.

Under pressure, this fluid acts on a series of brakes and clutches. With the aid of hydraulic valves and sensors, and governed by an electronic control unit (ECU) that monitors the demands on the engine and the vehicle’s speed, these brakes and clutches hold some gears while allowing others to turn, so producing a different gear ratio. Because the gears are always engaged, gear selection is smooth.

Constantly variable transmission (CVT)

The problem with automatic gearboxes is that they have only a few gears, so performance and economy are compromised. A CVT, on the other hand, offers an almost infinite number.

It does this by replacing the gears with a belt around two pulleys, one connected to the engine, the other to the transmission system.

In combination with the engine’s speed, a computer decides how to vary the pulley dimensions relative to each other. For example, when you pull away, the engine pulley is smaller than the transmission pulley but the opposite is true when you’re going quickly.

Theoretically, the car is always in the right gear for the engine revs. However, a CVT can sound like a slipping clutch so some car makers engineer in artificial pulley enlargement points to give a stepped feeling. Nissan markets a CVT system it calls Xtronic.