What are Brakes?

Brakes are one of the most important components in a vehicle. If you talk about performance it includes good brakes also, because if you go fast you need the same amount of stopping power to reduce that speed.

It is a mechanical device that absorbs energy from a moving system. It is used to slow or stop a moving vehicle, which is mostly accomplished using friction.

How the braking system works

Most modern cars have brakes on all four wheels, operated by a hydraulic system. The brakes may be disc type or drum type.

The front brakes play a greater part in stopping the car than the rear ones because braking throws the car weight forward on to the front wheels.

Many cars, therefore, have disc brakes, which are generally more efficient, at the front and drum brakes at the rear.

All-disc braking systems are used on some expensive or high-performance cars and all-drum systems on some older or smaller cars.

Brake hydraulics

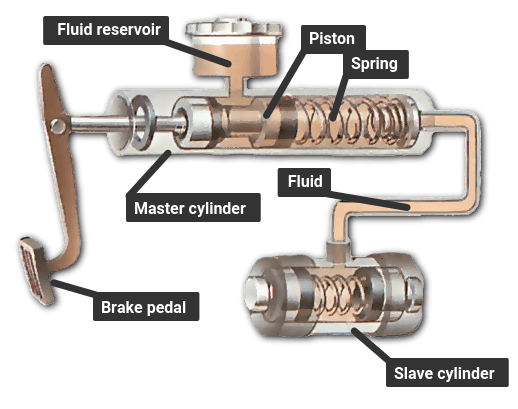

A hydraulic brake circuit has fluid-filled master and slave cylinders connected by pipes.

Master and slave cylinders

When you push the brake pedal it depresses a piston in the master cylinder, forcing fluid along the pipe.

The fluid travels to slave cylinders at each wheel and fills them, forcing pistons out to apply the brakes.

Fluid pressure distributes itself evenly around the system.

The combined surface ‘pushing’ area of all the slave pistons is much greater than that of the piston in the master cylinder.

Consequently, the master piston has to travel several inches to move the slave pistons the fraction of an inch it takes to apply the brakes.

This arrangement allows great force to be exerted by the brakes, in the same way, that a long-handled lever can easily lift a heavy object a short distance.

Most modern cars are fitted with twin hydraulic circuits, with two master cylinders in tandem, in case one should fail.

Sometimes one circuit works the front brakes and one the rear brakes, or each circuit works both front brakes and one of the rear brakes, or one circuit works all four brakes and the other the front ones only.

Under heavy braking, so much weight may come off the rear wheels that they lock, possibly causing a dangerous skid.

For this reason, the rear brakes are deliberately made less powerful than the front.

Most cars now also have a load-sensitive pressure-limiting valve. It closes when heavy braking raises hydraulic pressure to a level that might cause the rear brakes to lock and prevents any further movement of fluid to them.

Advanced cars may even have complex anti-lock systems that sense in various ways how the car is decelerating and whether any wheels are locking.

Such systems apply and release the brakes in rapid succession to stop them from locking.

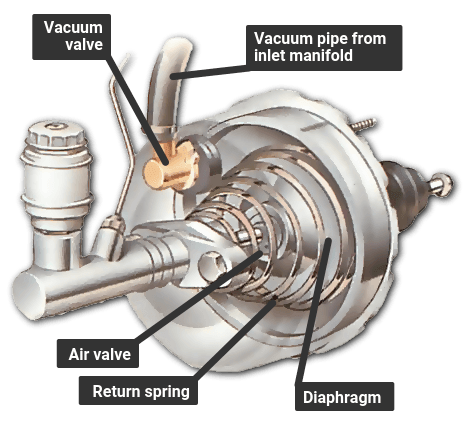

Power-assisted brakes

Many cars also have power assistance to reduce the effort needed to apply the brakes.

Usually, the source of power is the pressure difference between the partial vacuum in the inlet manifold and the outside air.

The servo unit that assists has a pipe connection to the inlet manifold.

Some cars have an indirect-acting servo fitted in the hydraulic lines between the master cylinder and the brakes. Such a unit can be mounted anywhere in the engine compartment instead of having to be directly in front of the pedal.

It, too, relies on the manifold vacuum to provide the boost. Pressing the brake pedal causes hydraulic pressure build-up from the master cylinder, a valve opens and that triggers the vacuum servo.

How the brake servo works

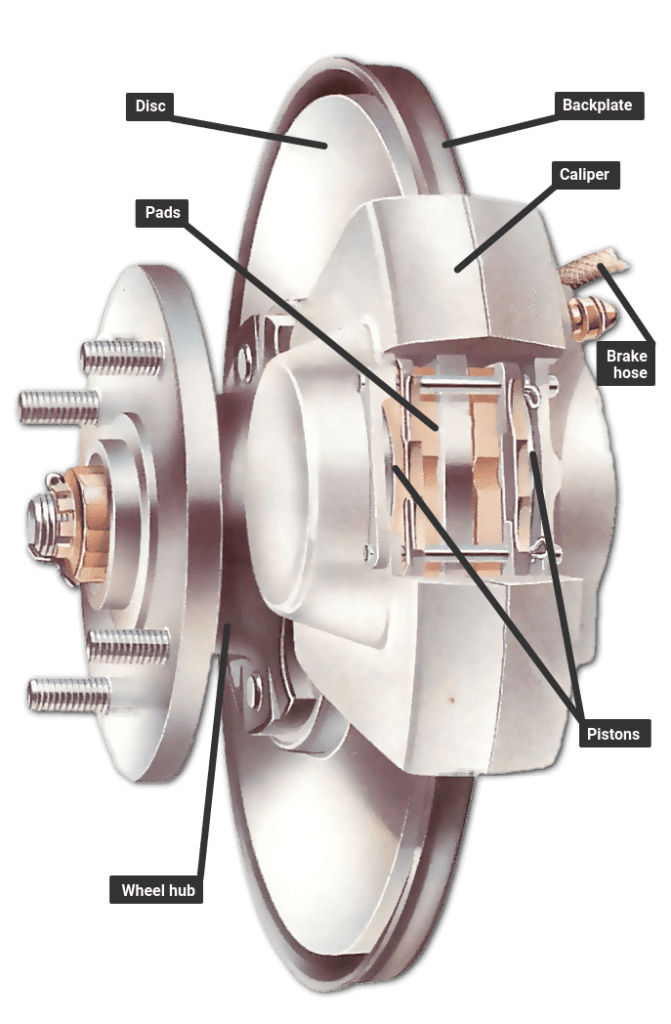

Disc brakes

The pressurized fluid enters the brake caliper forcing the brake pads to move inwards against the revolving disc (which is connected to the front wheels). When the brake pads come in contact with the disc, friction is generated which reduces the speed of the disc which in turn reduces the speed of the vehicle and eventually stopping your vehicle.

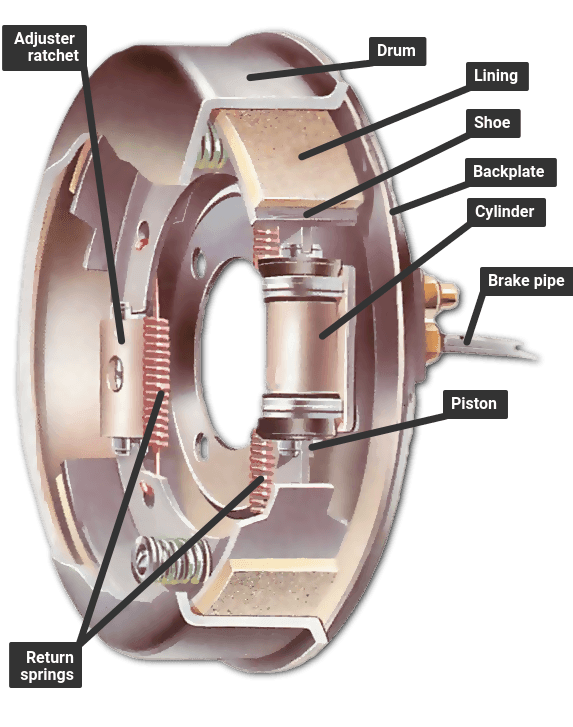

Drum brake

The pressurized fluid now enters the brake cylinder inside the Drum brakes. There is a piston inside these cylinders, these piston move outwards because of the brake pressurized fluid inside the cylinder. This outward movement of the piston causes the brakes shoes to move towards the rotating drum. When this brake shoes rub against the drum, friction is generated converting the kinetic energy into heat energy and thereby stopping your vehicle.

A drum brake has a hollow drum that turns with the wheel. Its open back is covered by a stationary backplate on which there are two curved shoes carrying friction linings.

The shoes are forced outwards by hydraulic pressure moving pistons in the brake’s wheel cylinders, so pressing the linings against the inside of the drum to slow or stop it.

Each brake shoe has a pivot at one end and a piston at the other. A leading shoe has the piston at the leading edge relative to the direction in which the drum turns.

The rotation of the drum tends to pull the leading shoe firmly against it when it makes contact, improving the braking effect.

Some drums have twin leading shoes, each with its own hydraulic cylinder; others have one leading and one trailing shoe – with the pivot at the front.

This design allows the two shoes to be forced apart from each other by a single-cylinder with a piston in each end.

It is simpler but less powerful than the two-leading-shoe system and is usually restricted to rear brakes.

In either type, return springs pull the shoes back a short way when the brakes are released.

Shoe travel is kept as short as possible by an adjuster. Older systems have manual adjusters that need to be turned from time to time as the friction linings wear. Later brakes have automatic adjustment by means of a ratchet.

Drum brakes may fade if they are applied repeatedly within a short time – they heat up and lose their efficiency until they cool down again. Discs, with their more open construction, are much less prone to fading.

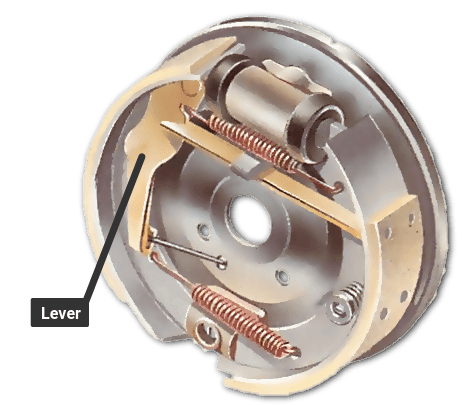

The handbrake

The handbrake mechanism

Apart from the hydraulic braking system, all cars have a mechanical handbrake acting on two wheels – usually the rear ones.

The handbrake gives limited braking if the hydraulic system fails completely, but its main purpose is as a parking brake.

The handbrake lever pulls a cable or pair of cables linked to the brakes by a set of smaller levers, pulleys, and guides whose details vary greatly from car to car.

A ratchet on the handbrake lever keeps the brake on once it is applied. A push-button disengages the ratchet and frees the lever.

On drum brakes, the handbrake system presses the brake linings against the drums.

These are the components used in brakes system:

- Brake Pedal: It is located in the center of the accelerator and clutch pedal. The brake system is activated only after pressing this pedal.

- Fluid Reservoir: It is the brake fluid or brake oil that is used on the braking system.

- Fluid Lines: These are pipes through which the brake fluid flows in the vehicle.

- Brake Pads: Steel backing plates used in disk brakes. It is usually made of ceramic, metal, or other hard-wearing composite materials.

- Brake Shoes: 2 pieces of sheet steel welded together that carry the brake lining.

- Brake Drum: It is the rotating drum-shaped component used in drum brakes.

- Rotor: It is a cast-iron brake disc connected to the wheel and/or axle, sometimes made of reinforced carbon-carbon, ceramic matrix, or another composite.

- Brake Lining: It is a heat-resistant, soft but tough material with a high friction characteristic housed inside a brake shoe.

- Piston: It is a moving component contained by a cylinder.

- Caliper: A device on which brake pads and pistons are mounted

- Floating Calipers/Sliding Caliper: It moves relative to the rotor; uses a piston on a single side of the disc to push the inner brake pad into the braking surface before pulling the caliper body in to apply pressure on the opposite side of the disc.

- Fixed Calipers: It does not move relative to the rotor and is sensitive to imperfections; it uses one or more single pairs of opposing pistons to clamp from each side of the rotor.

- Master Cylinder: A device that converts the non-hydraulic pressure from your foot into hydraulic pressure and controls slave cylinders at the opposite end of the hydraulic system.

- Vacuum Booster: A component used to enhance the master cylinder and augment pressure from a driver’s foot through the use of a vacuum in the engine intake; only effective while the vehicle’s engine is running.

When the driver presses the brake pedal there is a force generated which is boosted by the Vacuum from the engine. This boosting effect causes the brakes to respond more quickly.

This force from the vacuum booster pushes the piston inside the master cylinder against the spring force causing the brake fluid to flow under pressure. This pressurized fluid reaches the brake caliper(Disc Brakes) and brake cylinder(Drum Brakes) via fluid lines.

What is the difference between a brake and a braking system?

Think of a braking system as more of a ‘style’ of braking. This is the method behind the actual mechanics. The actual brakes describe the mechanical equipment used to carry out the method. We’re covering both in this article, as it’s important to be familiar with both the brake and its system.

Types of braking systems

- Electromagnetic Brake System Electromagnetic braking systems can be found in many new and hybrid vehicles. Electromagnetic brakes force the car to a stop by using an electric motor. Electromagnetic brakes are getting popular nowadays. It uses an electric motor that is included in the automobile which helps the vehicle come to a stop. It is mostly found in hybrid and electric cars and uses an electric motor to charge the batteries and regenerative brakes.

- Frictional Brake System It is the traditional braking system and commonly found in most of the automobiles. They are service brakes, and typically found in two forms; Pads(Disc) and Shoes(Drums). As the name implies, these brakes use friction to stop the automobile from moving. The pads are located on top of the disc which is rotating with the front wheel, and the shoes are located inside the drum which is rotating with the rear wheel. The pads will close in on the disc and stop the vehicle and the shoes will expand and rub with the drum to stop the vehicle.

- Hydraulic Brake System A hydraulic brake system is composed of a master cylinder that is fed by a reservoir of hydraulic braking fluid. This is connected by an assortment of metal pipes and rubber fittings which are attached to the cylinders of the wheels. The wheels contain two opposite pistons which are located on the band or drum brakes which pressure to push the pistons apart forcing the brake pads into the cylinders, thus causing the wheel to stop moving. This system works on brake fluid, cylinders, and friction. By creating pressure within the system it forces the brake pads to stop the wheels from moving.

- Servo braking system: Also known as vacuum or vacuum-assisted braking. With this system, the pressure applied to the pedal by the driver is augmented.

- Mechanical braking system: This system is one that powers the hand brake or emergency brake. Brakes are applied through mechanical linkages.

Types of brakes

The brakes you probably think of when you hear the word are your service brakes. These are the brakes that physically stop your car from moving and there are two types: the disc brake and the drum brake. Each car features two front brakes and two rear brakes. Most will either have all four as disc brakes or disc brakes in the front and drum brakes in the back.

- Disc brakes: Disc brakes are made up of a disc brake rotor, caliper, and brake pads. When pressure is applied through a hydraulic system the brake pads are pushed against the brake rotor, which causes the car to stop.

- Drum brakes: The main parts of a drum brake system are the brake drum, brake shoes, wheel cylinder, and brake springs. The brake shoes are contained within the brake drum, and when pressure is applied to the wheel cylinder, the brake shoes press against the drum, which causes the car to stop. The brake springs reduce drag by pulling the brake shoes back away from the drum when you take your foot off the brake pedal.

What are anti-lock brakes?

Not everyone agrees on whether anti-lock is a type of brake, a braking system, or simply a safety feature which makes the act of sudden braking a lot smoother for your car. Most new cars are fitted with anti-lock braking systems (ABS) and they work by preventing the wheels from locking up when the driver brakes suddenly. This helps reduce the overall stopping and aids control by preventing skidding, particularly in wet conditions.